Tribo-Mechanical-Activation-Microniser

NatraPak has brought Tribo-Mechanical Activation (TMA) micronising technology to New Zealand which is also known as TMAZ or TBM.

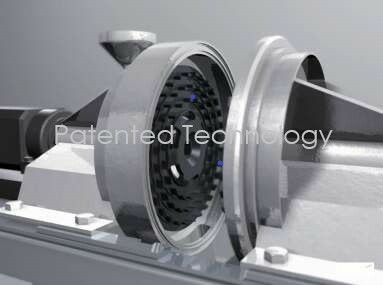

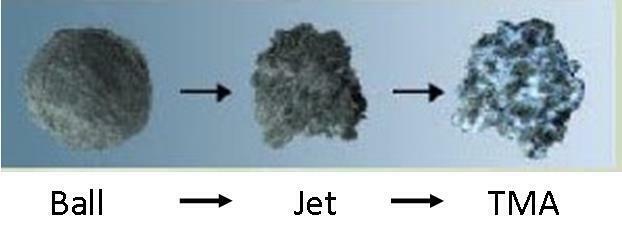

TMA (tribo-mechanical-activation) technology is the latest generation of mirconisation technology which is achieved using a specifically designed and patented TMA microniser. Unlike traditional ball and jet mills, TMA micronising employs a friction dynamic process - two rotor housing's are mated to one and another and operated by independent electrical motors spinning at over 22,000rpm.

In each rotor housing contains a rotary disk blades with concentric wreaths holding striking pins and blades, that are designed and arranged to pass each other freely while moving in opposite directions.

The rotor disk's also utilise a patented design that prevents unchecked passage of the material being processed, further increasing the efficiency of the micronisation process. Material is introduced through the central area of the rotor system through a vacuum process. It then passes between the rotor disk blades which creats an extremely turbulent environment increasing the collision and friction of particles in a short period of time. The resulting environment forces particles to collide at over 3,000km per hour. This centrifugal force created during the micronising process is enormous and each microniser requires excessive anchoring to remain stable.

Lorem Ipsum is simply dummy text of the printing and typesetting industry.

Lorem Ipsum is simply dummy text of the printing and typesetting industry.

TMA micronising exploits the full surface area of the chosen raw materials. This is very significant when compared to regular methods of milling especially, when particles sizes of one to ten microns are required. Raw material that has been micronised using the TMA system, can be micronised downn to a micron particle size - 1,000 smaller particle size compared to conventional micronising practices. It feels like cornflour when micronised.

The current form of milling or micronising with conventional methods such as ball-milling and jet-milling have limited factors and are now out-dated. The arrival of TMA technology has taken micronising to the next level, and has demonstrated to be more effective than the traditional methods.

The processing of one particle along the surface of another in these conditions exposes the materials structure, increasing bio-availability. The interaction and collision of particles not only micronises the particles to nano size, it also enlarges area by partially opening the surface and sub-layer of the structure. Thus, transforming the particles into an amorphous structure, altering the materials physio-chemical and energetic characteristics, lowering paramagnetism and increasing the available amoutn of electrons.

In simple terms, a uniform flaked particle size and shape, are some of the benefits of Tribo-Mechanical-Activation. This also greatly increases the surface area of the product, making it more reactive and more available for the human body or domestic animal to absorb and utilise, internally and externally.

There are many major European studies and scientific papers that have been conducted, using TMA processed Zeolite. NatraPak is cresting an extensive library of this information that is available. NatraPak is developing a process plant that will be to NZ Food Standards, which will open many markets locally and worldwide that require activated TMA raw materials. Dish of micronised zeolite